How to anodize titanium at home

Anodic oxidation of titanium forms a thin oxide layer on the surface. The layer itself is transparent, but different layer thicknesses cause different light interference, resulting in different color reflections. By changing the electric voltage, we can specifically influence the thickness of the oxides and create specific colors. Since the colors do not have pigment, they retain their saturation and do not fade even after years. In addition to titanium, niobium and zirconium alloys can also be colored.

.

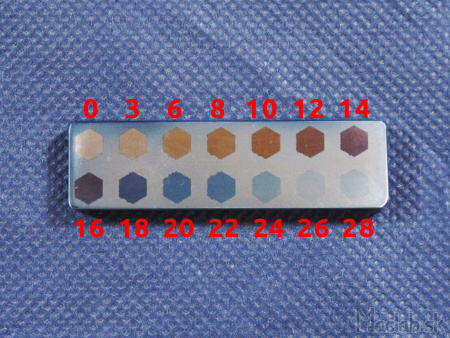

Thus, different stresses create a different thick oxide layer, on which color also depends. However, different titanium alloys contain different additive elements. Thus, they otherwise react to the electrolysis process. Therefore, it is advisable to test different stresses on a given material to begin with. The numbers in the figure indicate the voltage applied.

Titanium alloy plate on which we want to engrave a color picture.

The surface should be sanded and polished before dyeing.

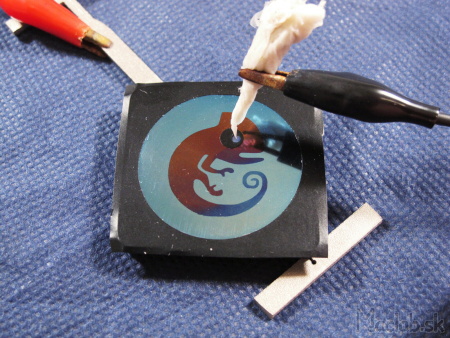

We will cover the places with different colors with an electrically non-conductive material. With a marker, nail polish, photoresist, ironing pattern printed on paper, vinyl plotter tape, shaped stickers or something similar. I used a plastic adhesive wallpaper.

The anodization of the titanium is performed as electrolysis, with the dyed object being connected to a positive electrode (+). Solutions of various acids or carbonates can be used as the electrolyte. I use sodium bicarbonate (baking soda bicarbonate). Approximately one teaspoon per 100ml of distilled water.

In order to achieve uniform colors, the electrodes should also be immersed in titanium. In an emergency, corrosion resistant (stainless) steel can also be used. The negative electrode should have sufficient surface area and distance from the colored surface. When the power is switched on, the surface starts to stain after a few seconds. I used 30V 1A. The dyed passivation layer is non-conductive and no longer flows after reaching the desired color.

Remove the mask and reveal a clean material surface.

Colors created at higher voltages will no longer change at lower electrolysis voltages because the thick layer passivates the surface. However, the colors of the lower voltage would overlap with the colors of the higher voltage because the layer thickness is increasing.

Color gradients can be created by gradual immersion of the colored object and simultaneously varying the voltage from higher to lower. Small areas can be selectively stained with cotton wool soaked in electrolyte.

Colors stand out in daylight. Because it is light interference, colors have different shades at different viewing angles. This gives the color a chameleon look.